Management Systems

“Quality Management System – a tool for the continuous improvement of an organization’s activities, which consists of the organizational structure, methodologies, processes, and resources required to manage and ensure quality”

The implementation of the QMS became the organizing foundation that allowed for increased employee responsibility, strengthened product quality control at all stages of its creation, improved the quality of finished products, and ensured the achievement of set goals and objectives.

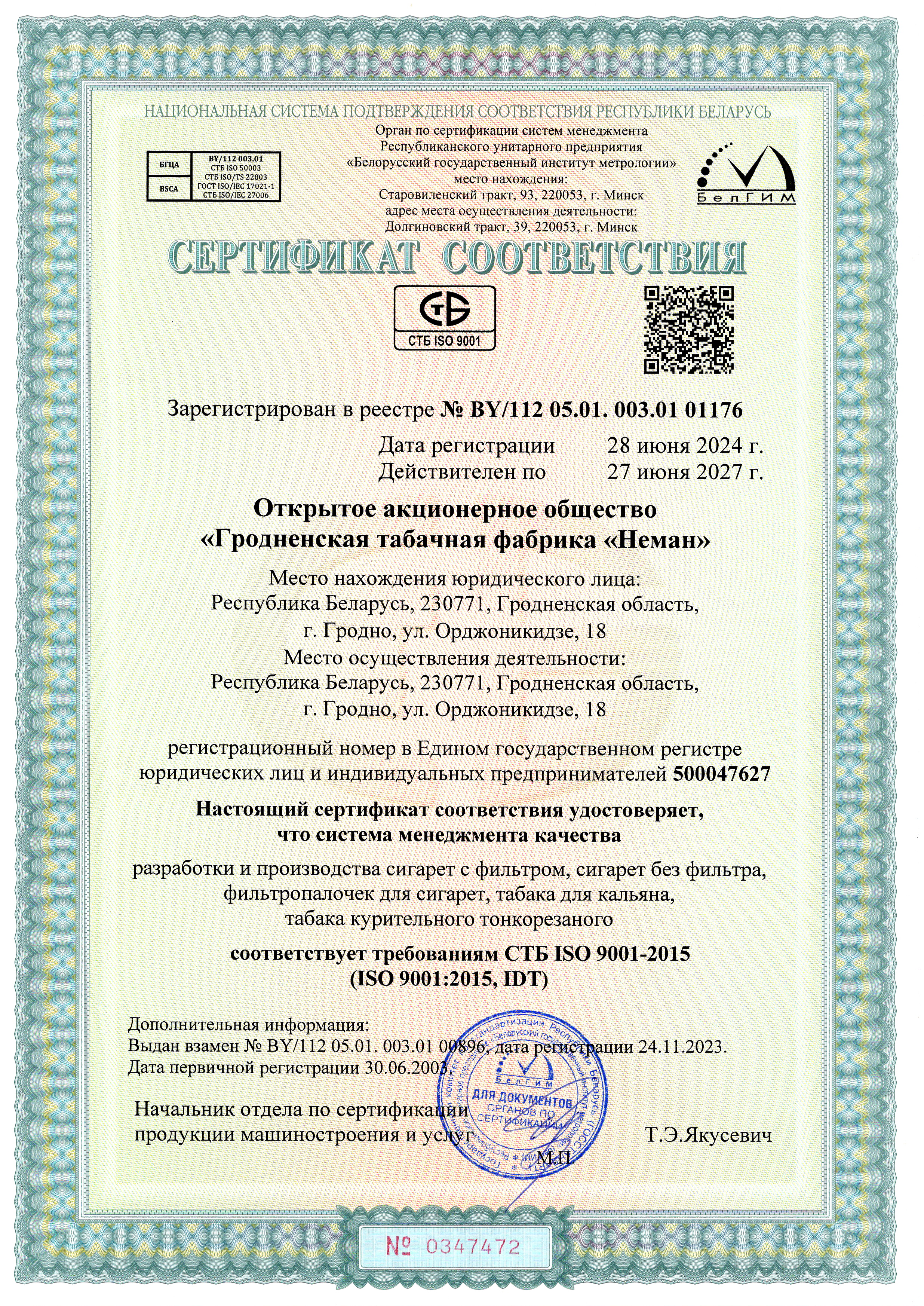

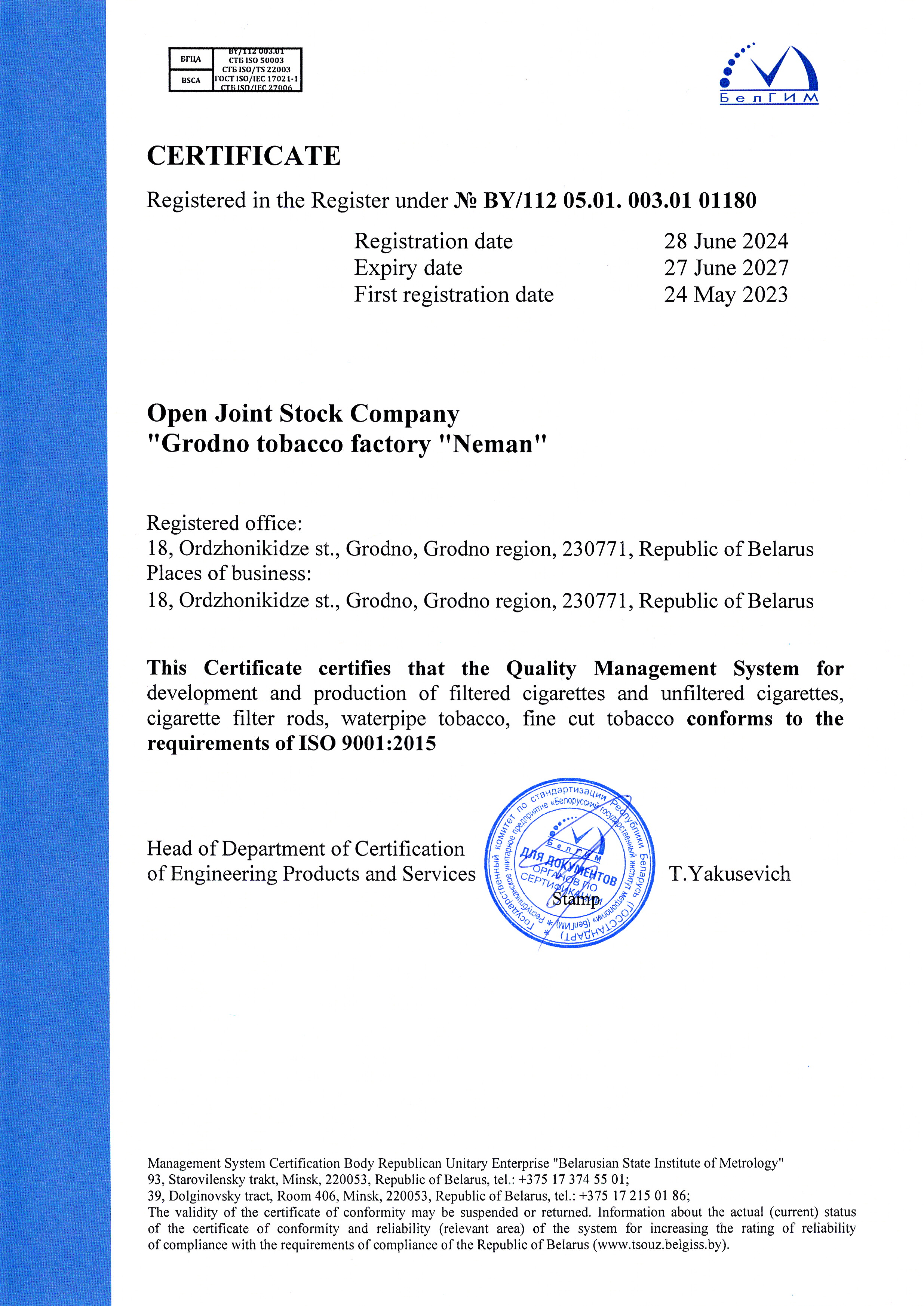

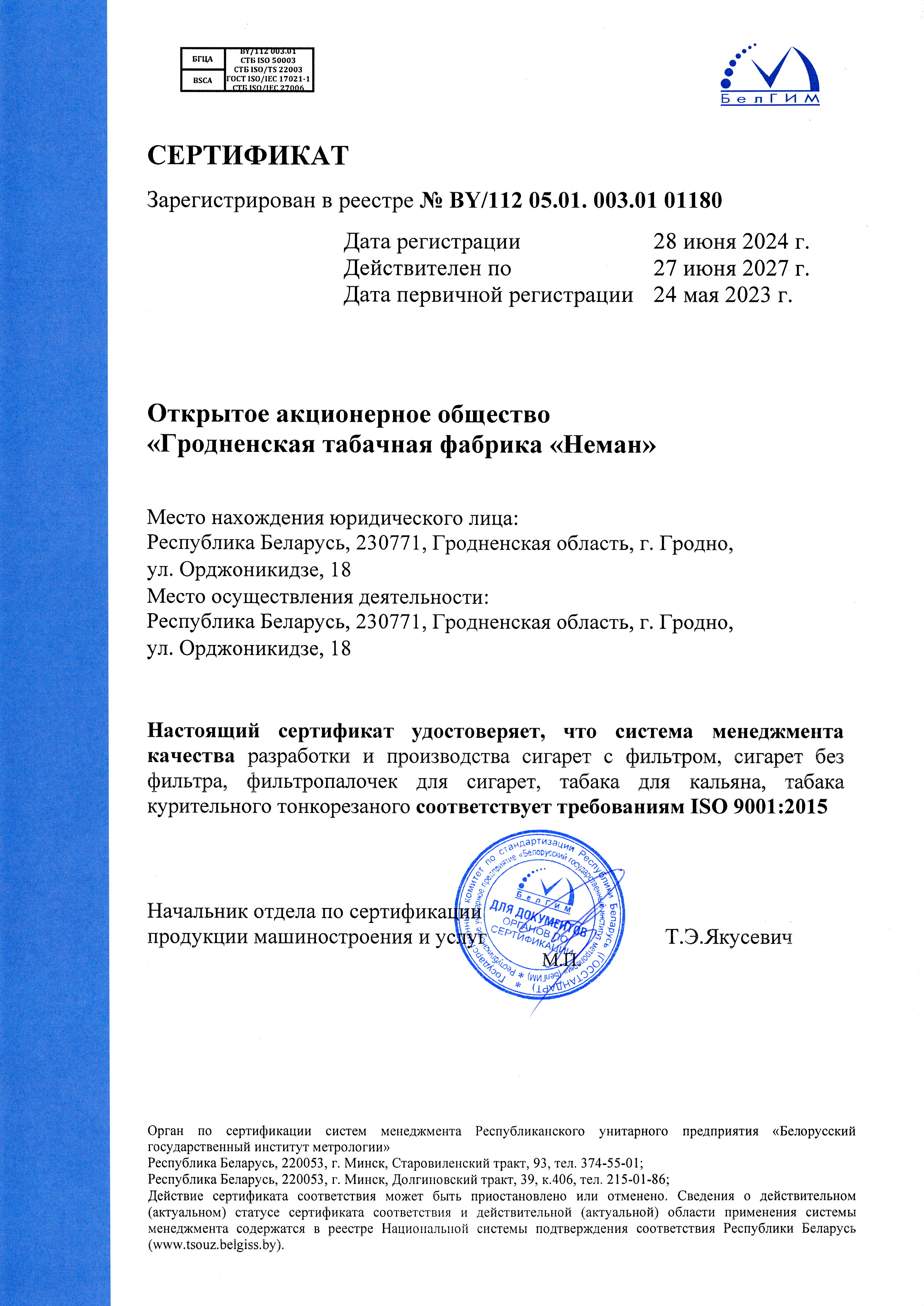

The correctly chosen development strategy, quality policy, labor protection, and environmental protection policy of OJSC “Grodno Tobacco Factory “Neman”, along with the high quality of new products (services), are confirmed by a certificate of conformity, which certifies that the quality management system for the development and production of filter and non-filter cigarettes, filter tips for cigarettes, hookah tobacco, and the performance of customer functions in construction, reconstruction, restoration, and landscaping activities complies with the requirements of STB ISO 9001–2015 (ISO 9001:2015, IDT).

In order to improve the efficiency of work on creating safe working conditions, the occupational health and safety management system has been certified in accordance with STB ISO 45001–2020.

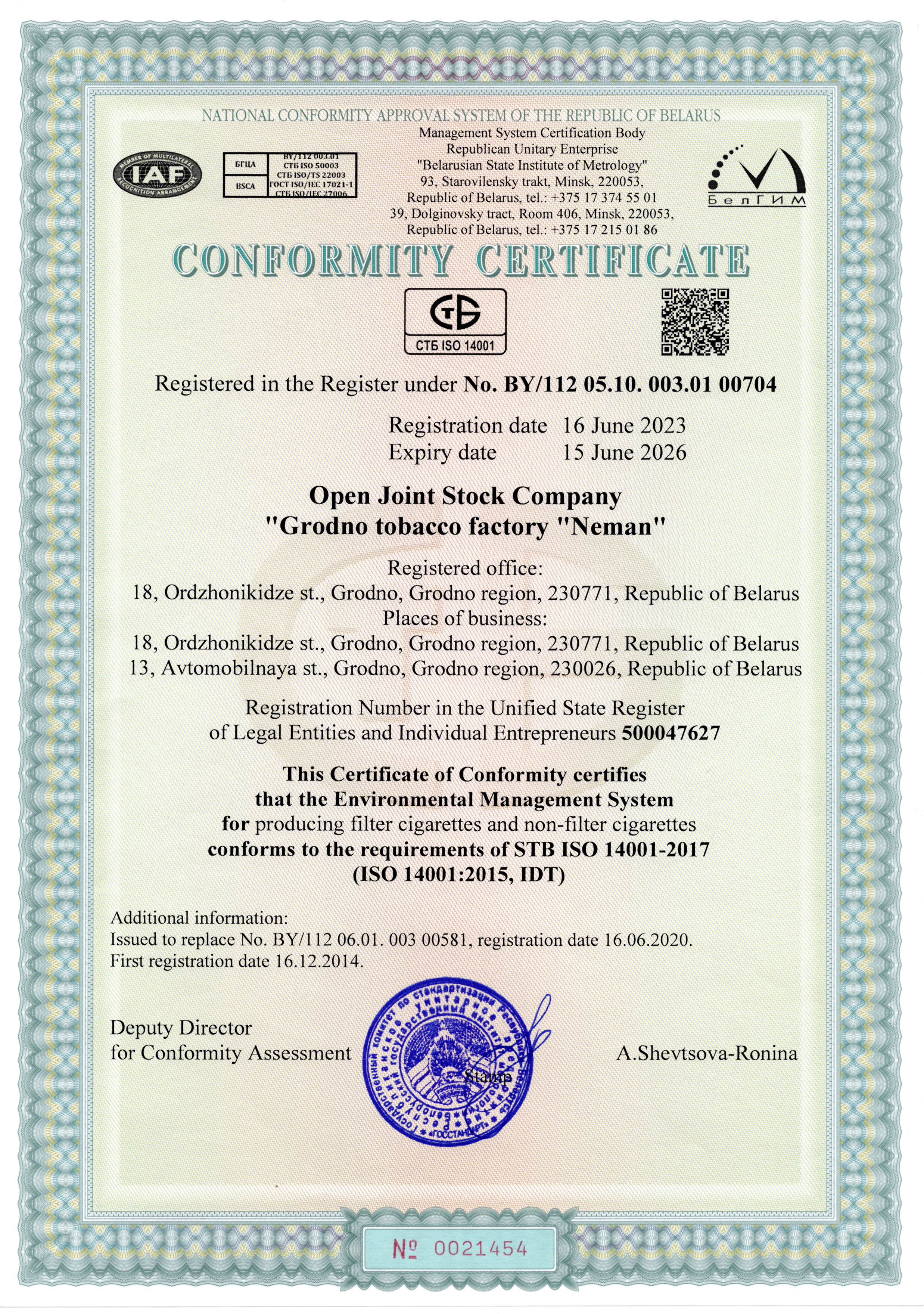

To enhance environmental safety and reduce harmful impacts on the environment, the environmental management system has been certified in accordance with the requirements of STB ISO 14001–2017.

In order to prevent, detect, and suppress actions that create conditions for bribery and to eliminate their consequences, as well as to strengthen the trust of all interested parties in the activities of OJSC “Grodno Tobacco Factory “Neman”, an anti-bribery management system has been certified for compliance with the requirements of STB ISO 37001.

The laboratory’s provision with modern laboratory equipment and qualified personnel has allowed for the receipt of an accreditation certificate for production control, confirming that the production control laboratory complies with the requirements of GOST ISO/IEC 17025–2019 (ISO/IEC 17025:2017, IDT).

OJSC “Grodno Tobacco Factory “Neman” ensures the safety and quality of its products through accumulated testing experience, modernization of technological equipment, modern laboratory facilities, continuous employee skill development, and active management systems

Ensuring compliance with safety and labor protection requirements by employees in the company is achieved through:

OJSC “Grodno Tobacco Factory “Neman” has implemented, certified, and operates a health and safety management system based on the STB ISO 45001–2020 (ISO 45001:2018, IDT) standard.

The collective agreement includes additional measures for moral and material incentives for employees who comply with occupational safety requirements. According to one of these measures, for the absence of accidents, occupational diseases, accidents, and incidents during the year, each employee is awarded a bonus.

In 2024, no accidents, fires, or other technological emergencies caused by the organization were registered at OJSC “Grodno Tobacco Factory “Neman” nor were there any workplace accidents or road traffic incidents